- Market leader

- Innovative & leading

- Safest technology

Vacuum truck for working with wet (hazardous) substances in industry

Vacuum trucks for WET hazardous substances

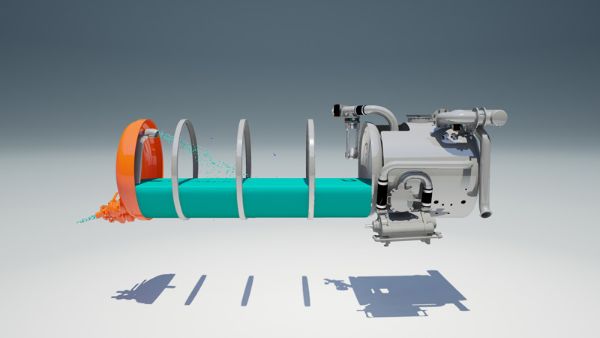

A wet substances vacuum truck is a vacuum truck upon which a vacuum tank is mounted; negative pressure (a vacuum) is applied to this tank by a vacuum pump. The negative pressure on the tank creates a pressure difference between its contents and the atmosphere. The resultant suction effect means air (gas) is discharged into the atmosphere via the vacuum pump. This is why wet substances trucks are also called pressure/vacuum trucks.

How a wet substances vacuum truck works

When using a wet substances vacuum truck, the product (which can be both liquid and/or sludge) is captured in the sludge tank as a result of this negative pressure. The vacuumed product does not go into the vacuum pump or the service water tank; only the vapours (gases) and particles go there. The shut-off valve/ball float on the intake of the vacuum pump comes into operation when the tank is full. In the event excess vapours (gases) are going to be released, a KOKS scrubber can be connected to clean them before they are released into the atmosphere.

Brief description of how a wet substances vacuum truck works

Brief description of how a wet substances vacuum truck works:

- Vacuum transport

The movement of the product is a result of the pressure difference - Volume increase

As the material makes the transition from the suction pipe connection (6”) to the tank (which is bigger than 6”), the liquid separates from the air flow - Filtration

Vapours/liquids are removed from the air flow in the service water tank - Venting

The remaining air flow is discharged through a vent pipe

Safety provisions for wet substances vacuum trucks

Wet substances vacuum trucks with ASME, DOT 407/412 and/or ATEX (Ex) certification are further equipped with various safety equipment that makes them suitable for the transportation of hazardous substances on public roads. These include, for example, impact/roll bars, tank locking, nitrogen connection, etc.

Main components of a wet substances vacuum truck

- Pressure/vacuum tank (sludge tank, service water tank and clean water tank)

- Pumps and drive (vacuum pump, high-pressure pump and compressor)

- Various control and operating systems (pneumatic, hydraulic and electrical)

- Various safety devices (nitrogen connection, rupture disk, clamp protection, rear cover safety, etc.)

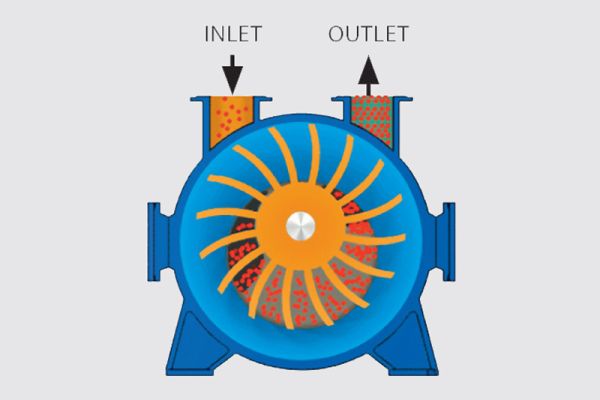

Liquid ring vacuum pump: one of the unique components

As the name liquid ring vacuum pump suggests, this type of pump features a liquid ring. There is no mechanical contact between the pump's moving parts. The liquid acts as small pistons, in much the same way as a traditional piston pump. As a result, the pump also develops very little heat and it is possible to achieve a deep vacuum.

When the pump starts, the liquid ring rotates at the same speed as the rotor. The rotor is slightly offset from the centre and the liquid ring features an array of small cells. A cell in the uppermost position is completely filled with water. As the cell turns, a pocket of air is created at the rotor hub.

The liquid acts as a piston as it moves away from the rotor hub to create a suction effect. As the cell passes the bottom of the chamber, the liquid begins pressing in towards the rotor hub. This causes the air to be forced out of the cell, filling it with liquid ready for the next suction cycle.

To separate the suction and compression parts of the pump, the ends of the casing are fitted with a flow plates and pump housing. Some pump types feature connections at both ends, while others (monoblock pumps) only have one at one end of the liquid ring.

Applications for use of wet substances in vacuum equipment

- Emergency clean-up

- Technical chemical cleaning

- Industrial cleaning

- Offshore activities

- Oil separation

- Onshore activities

- Petro-chemical activities

- Well cleaning

- Sewer cleaning

- Septic tank cleaning

- Shutdown cleaning work

- Silo cleaning

- Transport work

- Vacuum cleaning work

- Grease pit cleaning

- Water surface cleaning

- Collection of waste oil

- Municipal cleaning

- Ship cleaning

- Soil boring

- Pressuring liquids

- Oven cleaning

KOKS Group is an international manufacturer and supplier of vacuum trucks (DOT 407/412) and heavy industrial cleaning equipment. Founded in 1989 and has since grown into a dynamic company that operates globally and consists of seven specialised subsidiaries in the USA, The Netherlands, the Czech Republic, Saudi Arabia and participations in rental organizations that operate in The Netherlands and the United Kingdom. As a growing, innovative, healthy and reliable company, KOKS Group has gained an excellent reputation in the (petro)chemical sector and other industries as a vacuum truck (DOT 407/412) builder.

More information?

Do you have questions about the KOKS EcoVac wet vacuum truck (DOT 407/412). Just get in touch with our customer service desk. We are ready to help you, 24/7. Feel free to contact us!