Vacuum truck for working with dry (hazardous) substances in industry

Vacuum trucks with filter separator - dry

A dry substances vacuum truck (or super sucker) works on the principle of pneumatic transport (air movement). The vacuum tank on the vacuum truck is placed under negative pressure by the large amount of air displacement created by the blower. The air loses its speed in the tank due to the volume increase, as a result, it will no longer be able to carry large quantities of product. In particular, heavier particles will drop down. The air and product is then thrown against the back of the vacuum tank, so the speed decreases even more and even more product drops down. This is why dry substances vacuum trucks are also called air movement trucks.

In a dry substances vacuum truck, the product, which can be both dry and wet, enters the vacuum tank by means of air displacement. The vacuumed product does not end up in the filters and blower; only the vapours (gases) and dust particles go there. There are two types of sensors (one for dry substances and one for wet substances) on the sludge tank, and they come into operation when the tank is full. In the event of surplus released vapours (gases), a KOKS scrubber can be connected to clean them before they are released into the atmosphere.

Need thorough advice?

We can imagine that you would like to know more about our products, the fields of application and our company. Make an appointment without obligation to get to know us and our extensive range of industrial cleaning machines.

We will be more than willing to tell you why thousands of professionals worldwide trust KOKS Group and KOKS equipment.

You can contact us by calling +31 (0)72 540 66 99, by emailing info@koks.com or by filling in the contact form via the link below. On working days we are available between 07.30 and 17.00 and we are happy to be of service.

Filter separation

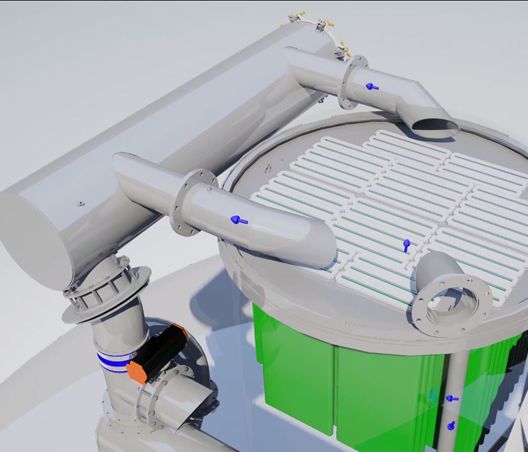

To prevent the dry substances ending up in the blower, all trucks are fitted with a filter system. This filter system consists of filter bags, which are found at the front of the vacuum tank in a filter chamber, such as can be seen on the KOKS MegaVac. There are 42 filter bags in the filter chamber through which the air is sucked. These filter bags collect the fine dust and must be cleaned regularly.

There are two ways to do this:

- Pneumatic (standard): a strong air blast against the inside of the filter bags causes the dirt from the filter bags to fall out of the filter chamber. The intermediate door must be then opened to get the product out.

- Mechanical: pneumatically operated beaters (shaking or vibrating).

Short description of a dry substances vacuum truck with filter separator

- Volume increase

As the air makes the transition from the suction connection (which is 8”) to the tank, the heavy parts drop to the bottom of the tank. - Labyrint

Provides an air refraction, which reduces the speed of the lighter particles, which also drop to the bottom. - Filter bags

Finally, the floating parts are removed from the airflow by the filter bags.

Safety provisions for dry substances vacuum trucks

Dry substances vacuum trucks with ADR/Ex/PED approval are equipped with various additional safety equipment, which make them suitable for the transportation of hazardous substances on public roads. These include, for example, Impact-absorbing/roll bars, tank locking, nitrogen connection, etc.

Main components of a dry substances vacuum truck with filter separator

- Pressure/vacuum tank (dirt tank and filter chamber)

- Pumps and drivetrain (transfer case and blower)

- Filter installation (filter bags and cyclones)

- Various (exchangeable) rear doors (blow, liquid and loose lid)

- Various safety equipment (earthing reel, rupture disk, clamp protection, rear door safety lock, etc.)

Types of dry substances suitable for vacuum trucks and equipment

The operation of a dry substances vacuum truck is based on the movement of substances due to the movement of air, or pneumatic transport. The KOKS MegaVac and the KOKS CycloVac are dry substances vacuum trucks that work on this principle. There is also self-supporting vacuum equipment for dry substances, such as the KOKS MegaVac Loader, KOKS CycloVac Cyclone Loader and KOKS MegaVac Container.

Overview of the applications in which dry substances equipment is used

- Emergency clean-up

- Catalyst work

- Ground suction/excavation work

- Industrial cleaning

- Onshore activities

- Petro-chemical activities

- Pits cleaning

- Sewer cleaning

- Shutdown cleaning work

- Silo cleaning

- Transport work

- Vacuum cleaning work

- Water surface cleaning

- Ship cleaning

- Ballast suction

- Suction and blowing of liquids and solids

- Pressuring liquids

- Oven cleaning

- Fly ash removal

- Blasting grit suction

- Blast furnace slag suction

- Stable/stall cleaning

- Crawl space cleaning